Products

2차메뉴

3차메뉴

MSL-LL-26(F)4A

Floating Ocean Weather Observation System Using New Materials(EPP)

Designed with distributed buoyancy structure for measurement precision and safety.

● International organization (IALA) eco-friendly recommendation standard application

The buoyancy material is made of EPP (Expanded polypropylene), an eco-friendly material, and the surface of the buoyancy material is coated with eco-friendly polyurea to improve durability

| IALA Guideline 1077 Maintenance of AtoN |

IALA Guideline 1036 Environmental Management in AtoN |

IALA Guideline 1015 Painting aids to navigation buoys |

|---|---|---|

| < Aids to Navigation Maintenance Guidelines > |

< Guidelines for Environmentally Friendly Management of Aids to Navigation > | < Guidelines for Prevention of Shellfish > |

| As a basic principle of AtoN maintenance strategy, the use of eco-friendly products and materials is recommended as away to “minimize impact on the environment”. | Since synthetic products cannot be recycled and must be treated as idustrial waste, it is recommended to select renewable buoys and moorings. | To prevent shellfish, it is recommended to use non-toxic coatings(slippery) and silicon-based coatings. |

●Verification of the safety of the buoy by an authorized institution

| Sortation | Von mises stress(MPa) | Remark | Note | |

|---|---|---|---|---|

| Evaluated Buoy Stress | 211 ① | |||

| L O A D | Weather(Wind,Wave..) | 11.3 | Ok | 5% Of ① |

| Ship Collision (Top) | 15.7 | Ok | 10% Of ① | |

| Ship Collision(Bottom) | 128.6 | Ok | 61% Of ① | |

| Evaluation Result | Stable even when applied simultaneously | |||

Stability against external forces such as weather conditions and ship collisions

● LiDAR and marine weather measurement system

Verified Lidar ZX300M (Remote wind condition measurement 10~200+ meter)

●MSL - Floating Lidar System Marine installation

-

① On-site transportation of light buoys (disassembled state)

① On-site transportation of light buoys (disassembled state) -

② Assembly of light buoys on-site

② Assembly of light buoys on-site -

③ Offshore installation of buoys (using auxiliary tools)

③ Offshore installation of buoys (using auxiliary tools) -

④ Installation (4 Sinkers)

④ Installation (4 Sinkers) -

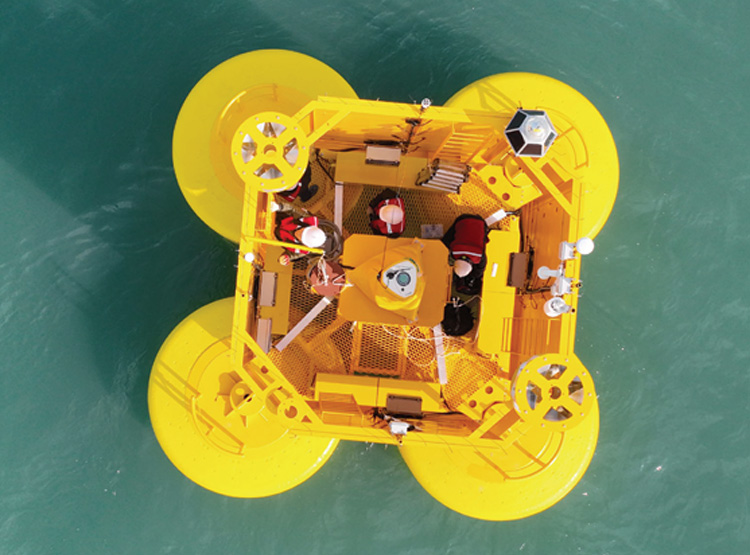

⑤ Offshore installation completed (Front)

⑤ Offshore installation completed (Front) -

⑥ Offshore installation completed (Top)

⑥ Offshore installation completed (Top)

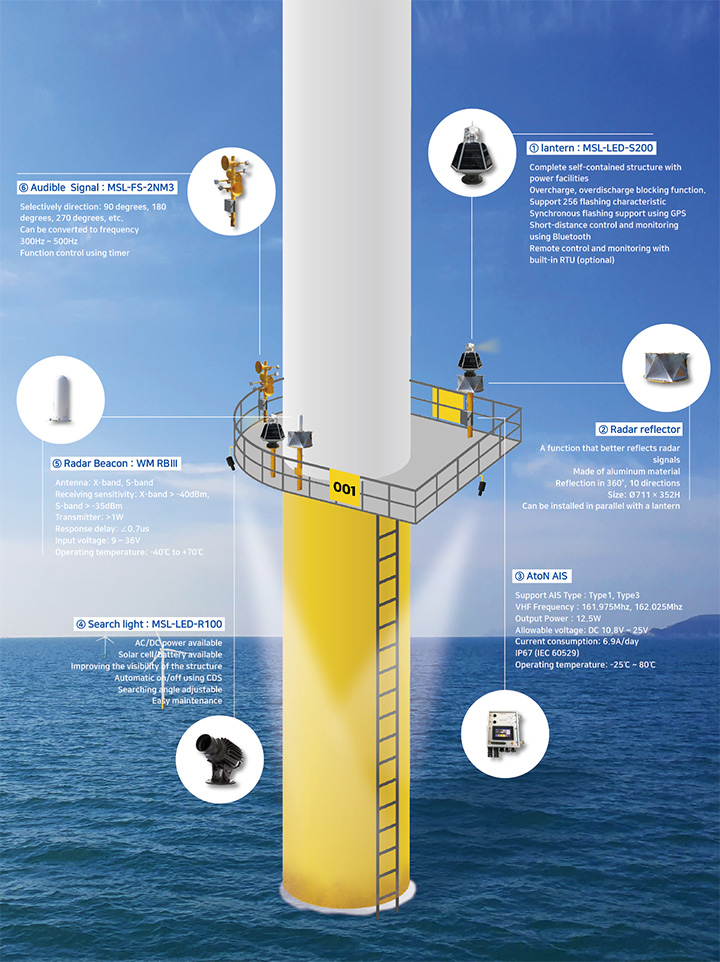

●AtoN Equipment Installation and Specifications

- Depending on the purpose, it is possible to manufacture buoys of various sizes, and the buoyancy material is applied with EPP material to reduce human life as well as damage to the colliding vessel and light buoy due to collision with the vessel. Light weight makes installation and maintenance easy, and the use of eco-friendly materials contributes to the prevention of marine pollution. Polyurea coating is applied to the outside of the EPP buoyant material to improve durability and safety from ship collisions.

* EPP : Expanded Polypropylene.

| Technical Specification | |||

|---|---|---|---|

| Light Buoy For Observing Marine Wind Condition | Measurement System | ||

| Model Name | FLS-LL-26(F)4A | LiDAR | ZX300M(10~200m) |

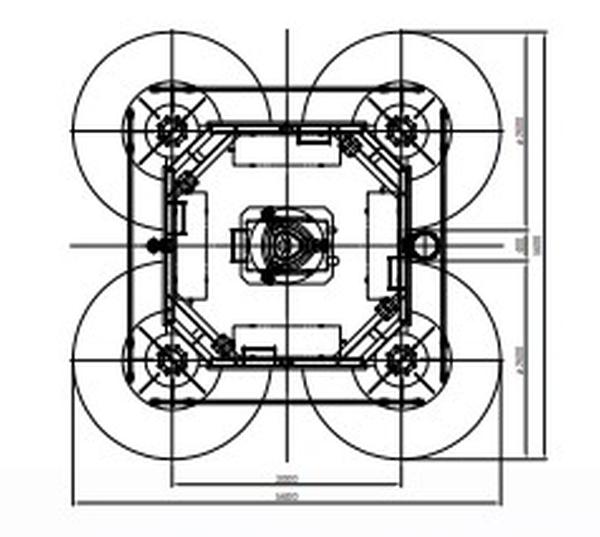

|

Structure |

Horizontal rectangle (prefabricated hollow structure) |

Wind Direction And Speedometer |

0~360° / 0~100m/s |

| Buoyant Material | EPP+POLYUREA | Thermo-Hygrometer | -80℃~60℃ / 0~100%RH |

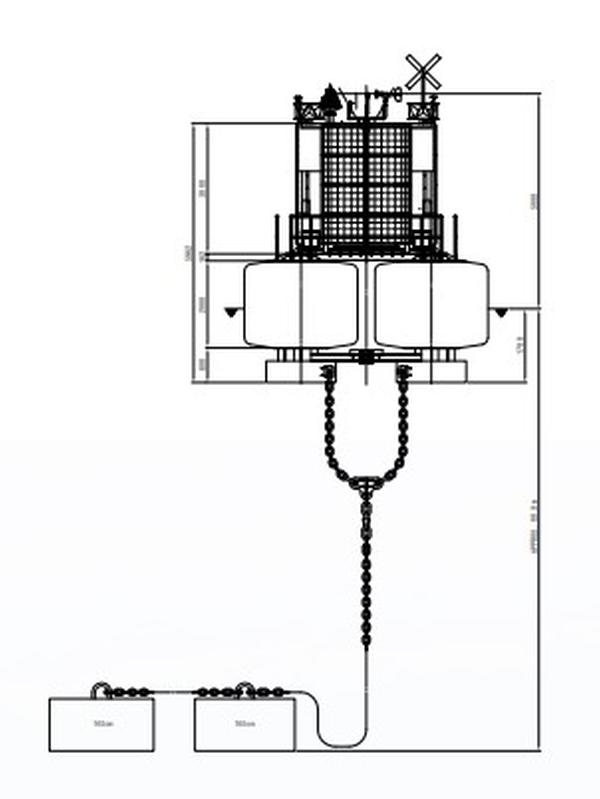

| Size | 5.6m × 5.6m × 6.0m(H) | Barometer | 500~1100hPa |

| Weight | 20.0ton | Wave Gauge | Wave height 30m, period 1.42~33s, wave direction 0~360° |

| Lantern | 7NM/all-in-one (built-in RTU) | Directional Flow | 70m |

| Radio Beacon | AtoN AIS | Monitoring And Recording Device | CCTV, COMPASS, DATA LOGGER |

| Radar Reflector | Aluminum, 2EA | Communication Method | LTE , satellite communication |

| Topmark | Special mark (X shape) | Power Facility | Solar panel 3.2KW |

| Chain | Ø38㎜ (Changeable according to sta -bility review) | Water Temperature | -20℃~80℃ |

| Sinker | 16ton, 2EA (Changeable according to stability review) | Conductivity | 0~200mS/cm |

| Mooring | 2-POINT | Salt | 0~70PSU |